WHAT IS BLAZE®?

BLAZE® is the revolutionary metal surface treatment with the highest wear and abrasion resistance of any technology in the market today

What is BLAZE?

BLAZE is a next-generation Boron-diffusion process that converts the surface of metal components to become extremely resistant to corrosion and abrasion while being completely environmentally friendly.

Environmentally Friendly

BLAZE is an environmentally friendly process and product that your company can benefit from.

Resistance and Friction

BLAZE has the highest wear and abrasion resistance of any technology available on the market (Per ASTM G65). BLAZE surfaces are non-brittle, non-spalling, fully weldable, and have a very low coefficient of friction.

We Call It Boronization 2.0

BLAZE is “Boronization 2.0” since its proprietary formulation has overcome the drawbacks of conventional Boronization. It is also very easy to selectively process specific areas—unlike the antiquated pack process.

Little to No Dimensional Change

BLAZE causes ZERO dimensional change in typical applications, since it’s not a coating. This is a huge advantage, because you pre-machine to exact tolerances, and there is no need for redesign or re-engineering of your component.

Best Performance

BLAZE is a cost-effective, higher-performing replacement for many lesser finishing processes, including Boronizing, Carbonitriding, Carborization, CVD, Hexavalent Hard Chrome, HVOF, Nitriding, PVD, and many exotic alloys.

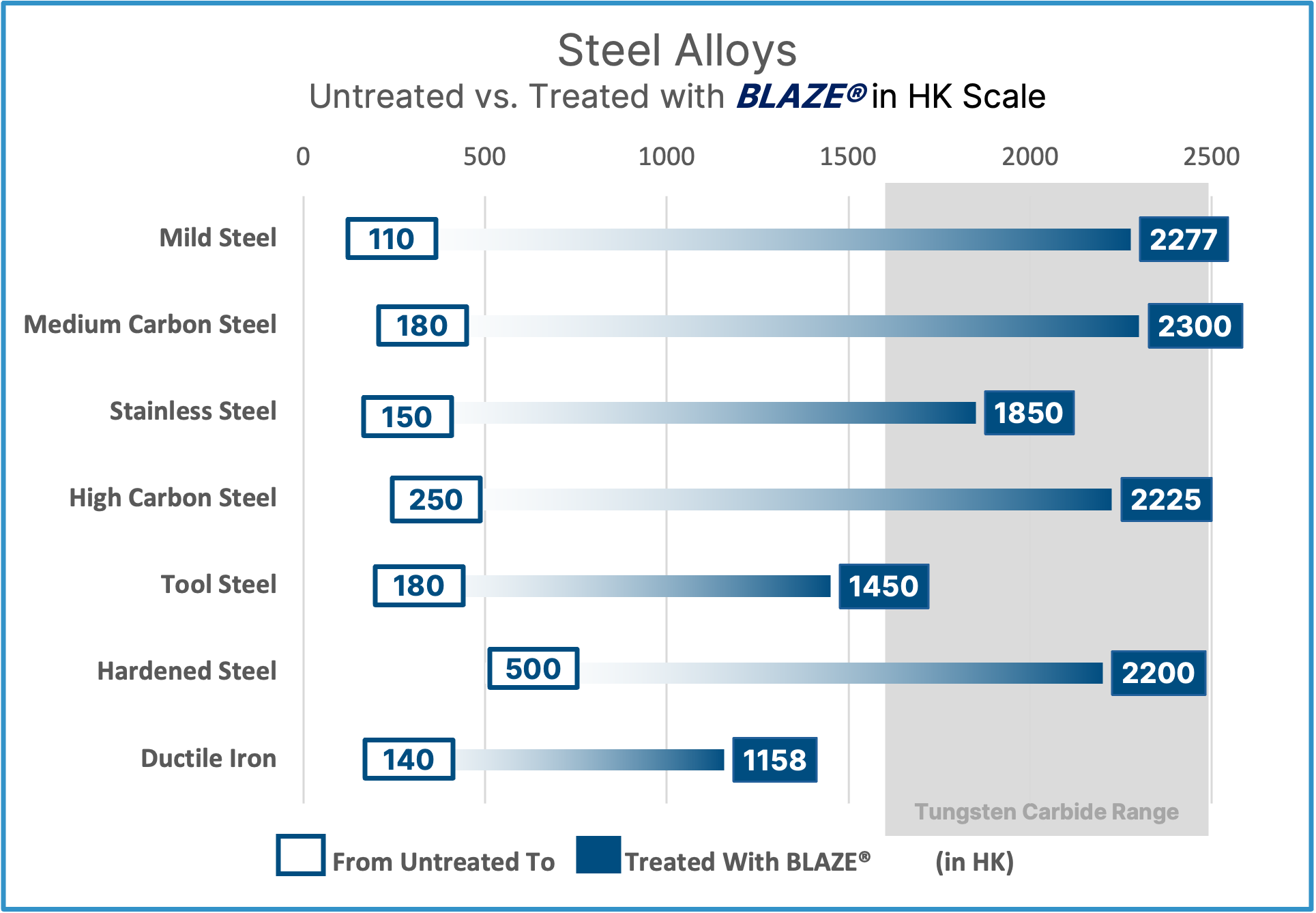

EXTREME SURFACE hardness

BLAZE delivers extraordinary surface hardness — even for unalloyed steel! On the Knoop scale, it achieves a hardness of 1800 to 2200. And in the familiar Rockwell C chart, which tops at at 72 HrC, BLAZE tops the scale with almost all Steel Alloys, with better results in most cases than Tungsten Carbide at a much lower cost.

It’s tougher than tungsten carbide, harder than titanium nitride, harder than hard chrome. And you don’t have to worry about the brittleness of other technologies.

contact us!

Feel free to get in contact with us using the form below, and we will respond back to you ASAP.

If you require an instant response, please give us a call.